«ОЛАНД ПРОМ ІНЖИНІРИНГ» пропонує послугу гнуття заготовки по радіусу профільного, сортового металу з січенням різної геометричної форми.

«ОЛАНД ПРОМ ІНЖИНІРИНГ» пропонує послугу гнуття заготовки по радіусу профільного, сортового металу з січенням різної геометричної форми.

Our company has the necessary machines and equipment for bending pipes, angles and rolled metal, as well as rolling of sheet metal.

Experience allows us to make details of complex geometry. The details below show the profile type, maximum profile cross-sections and minimum inner diameter.

We perform profile rolling work and rolled metal in all regions of Ukraine. The metalworking shop is located in Kalush, Ivano-Frankivsk region.

To clarify the terms of cooperation, you can call our specialists by phone +38(0342) 71-57-27; +38(068) 346 86 12

| Profile view | Max. profile section, mm | Min. inner diameter, mm |

| |

50x50 | 800 |

| 20x20 | 400 | |

| |

80x20 | 1200 |

| 50x10 | 400 | |

| |

120x25 | 600 |

| 50x10 | 400 | |

| |

UPN 120 UPN 60 |

800 500 |

| |

UPN 120 UPN 60 |

1200 600 |

| |

80x9 | 1000 |

| 40x5 | 400 | |

| |

80x9 | 1200 |

| 40x5 | 500 | |

| |

80x9 | 1200 |

| 40x5 | 400 | |

| |

70x3 | 1600 |

| 40x2 | 500 | |

| |

80х40х3 | 1400 |

| 40x20x2 | 500 | |

| |

Ø50 | 800 |

| Ø20 | 400 | |

| |

Ø100x2 | 1600 |

| Ø60x2 | 500 | |

| |

Ø3 ″ x 3.2 | 1600 |

| Ø1 ″ x2.6 | 500 | |

| |

70х70х7 | 1000 |

| 40x40x5 | 500 | |

| |

70х70х7 | 1200 |

| 40x40x5 | 600 |

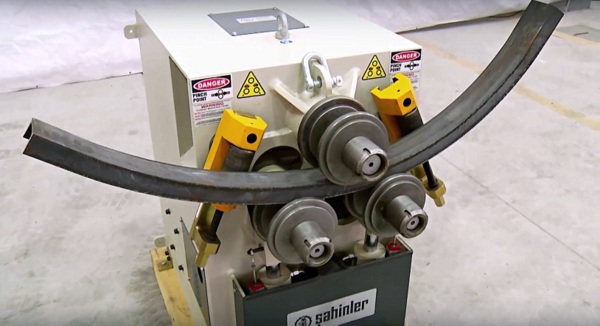

Rolling of shaped metal is performed on a special rolling machine on three-roll machines (rollers), which allows us to form visors, composite columns, rounded friezes and more. The application of this technology implies the deformation of the shaped metal or profile in one of the directions due to the large radius of curvature. The material (profile), passed through the rolls of the rolling machine, takes the form of a cylinder.

In fact, rolling (metal rolling) is a technology of deformation of metal using special tools or equipment (so-called rollers). A roller (also known as a roller or roller) is a working part of a machine (machine) consisting of several rollers rotating in different directions. The processed material moves between them. The rollers have a limit on the thickness of the metal and the minimum rolling radius.

Metal rolling is widely used to change the shape of plastic metals, and the result is ready-made blanks and parts suitable for further connection. During rolling, the material (metal) is deformed at a given angle, acquiring a cylindrical shape.

Russian

Russian OLAND

OLAND