Flat and conical bottoms can be made at our factory with the following parameters of diameters and wall thickness:

Diameter: from 600 to 3500 mm

Wall thickness: from 1.5 to 16 mm

Characteristics of the machine for flanging (flanging) and radial cutting of sheet metal:

Flange (flanging)

Maximum sheet thickness at 500 N / mm²

16 mm

The maximum diameter of a round workpiece

3600 mm

Open gap in the housing (workpiece height)

1000 mm

The diameter of the blades of the cutter

250 mm

Speed of running-in (cutting), standard

12 mm / min

Equipped with an inclined shaft for the lower cutter, which provides clean cutting of the inner and outer diameters of roundings and rings, as well as reduces the wear of the edges of circular knives

Automatic or semi-automatic operation with cam control or CNC.

High cutting accuracy due to automatic entry into the cutting wheel and rigid mechanical connection between the machine body and the clamping arc.

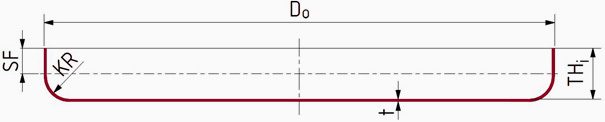

Designation of parameters of flat and conical bottoms:

Technical data, abbreviations:

Do = outer diameter of the bottom

Di = inner diameter of the bottom

CR = radius of curvature

KR = flange radius

SF = board height

DH = height of the curved part

THi = total height of the bottom from the inside

t = wall thickness

Russian

Russian OLAND

OLAND