«ОЛАНД ПРОМ ІНЖИНІРИНГ» пропонує послугу rolling and bending of sheet metal.

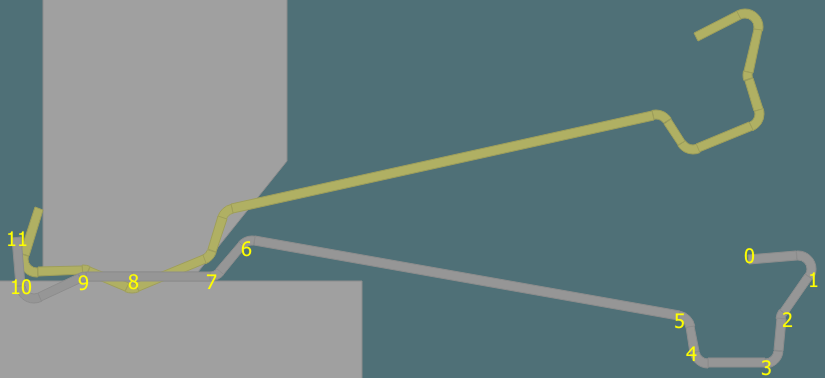

We make shells and pipes of different diameters, thicknesses and cross sections.

Rolling of sheet metal perform on four-roll bending machines (rollers) width 2.5m and 3.0m.

For bending of sheet metal we use a multifunctional sheet bending press with CNC bending force 220 tons.

Equipment what the company uses for rolling and bending services is a great solution for production round tanks, straight-seam air ducts, drains, ventilation, blanks for shaped parts, radial products .

This allows us to shape elements of pneumatic transport, transitions, branching, composite columns, elements of containers and rounded friezes, etc.

Four-roller machine S4R HMS 2550x220:

Rolling of sheet metal

Maximum sheet width

2500 mm

Maximum sheet thickness

25 mm

The minimum diameter of the workpiece

242 mm

Without bending, the straight section at the ends of the sheet depends on the diameter

Hydraulic system of lateral support of a sheet of big diameter

How is the rolling process?

- The calculation of the length and radius of the workpiece

- Customizable equipment

- According to the calculations, the workpiece is provided with the required size (rolling process)

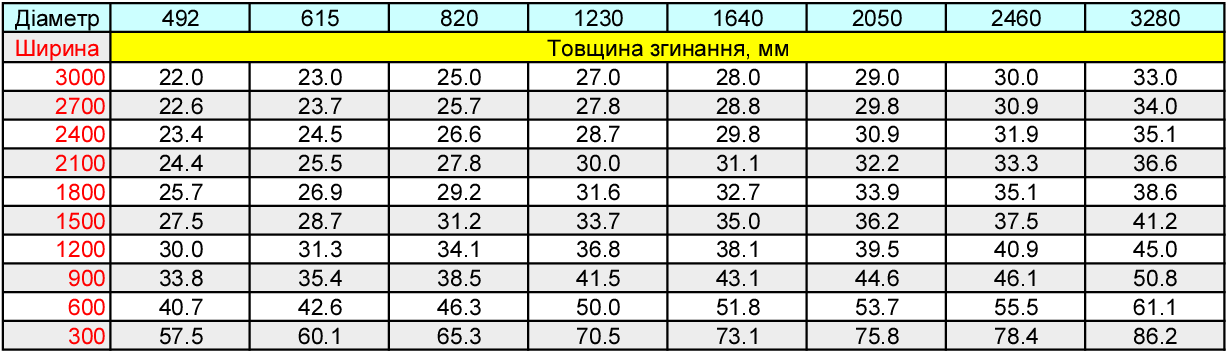

Four-roll machine VB3000 / 21/19:

Rolling of sheet metal

Maximum sheet width

3000 mm

Maximum sheet thickness

86.2 mm

The minimum diameter of the workpiece

492 mm

The crane for support of sheets of big diameter

Limit of plastic deformation of metal

Hydraulic system of lateral support of a sheet of big diameter

Without bending, the straight section at the ends of the sheet depends on the diameter

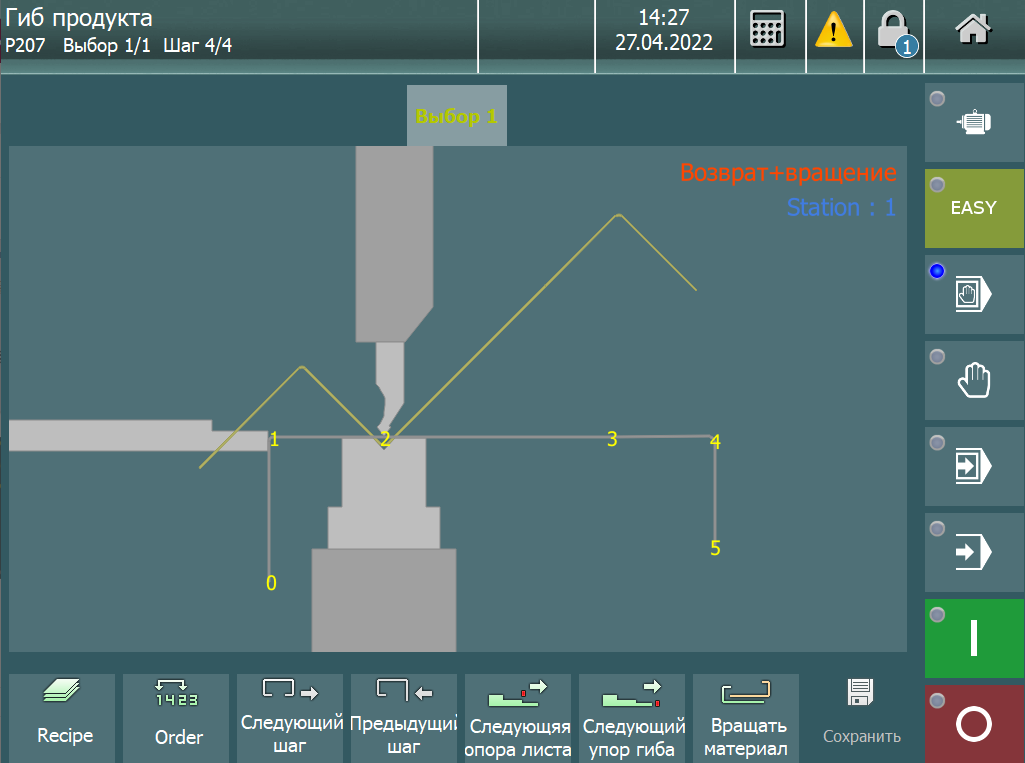

Sheet bending press Durma AD-R 40220:

Bending of sheet metal

Bending effort

220 tons

(A) The length of the bend

4050 mm

(B) The distance between the racks

3600 mm

(C) Course

265 mm

(D) Clearance

530 mm

(E) Cutout in racks

410 mm

(F) Table height

900 mm

(G) Table width

104 mm

Russian

Russian OLAND

OLAND  Rolling of sheet metal

Rolling of sheet metal